There was a time when remote controlled aeroplanes were expensive and difficult to fly, and remote-controlled helicopters were unaffordable and near impossible to fly. Those of us with dreams of flying our own machines or built your own drones were left to look on from the sidelines, unable to participate.

Image source: Pixabay

We have been fortunate then, over the last couple of decades, to witness a technological revolution in manufacturing that has brought flight to within the reach of almost anyone. Powerful yet lightweight electric motors, coupled with batteries that have undreamed-of capacities, on machines made from advanced materials by precision mass production techniques, have given us aircraft for pocket money prices. Not only has this been a revolution in terms of cost, it has also given us entirely new craft that would have been impossible to fly before the advent of the computing power required to keep them in the air. A multirotor, commonly referred to as a drone, would have been impossible to fly by any other means than with the help of a computer to keep it in trim, yet now, due to their very low moving parts count, they are the cheapest and most commonly seen form of remote controlled flight. Multirotors have become a part of hackspace culture in a way that other craft have not, so let’s take an in-depth look at them and understand how they are built.

There are many different types of multirotor, each of which has its own characteristics and applications. A racing quadcopter with extreme

maneuverability, for example, will be completely different to an octocopter used by a broadcaster to carry a TV camera that requires stability and long flight time. It’s time to look at just a few of the types you will commonly find.

These machines invariably have little brushed DC motors and very limited outdoor capability, but their flight characteristics are such that, if you can master one, you should find flying a more capable machine to be no problem.

As the budget increases in the field of ready-to-fly multirotors, so do the capabilities of the models in question. The more expensive toy machines now have on-board first-person-view video transmitters and, as the price increases, there is a transition from the world of toys to that of serious machines.

The motors have become brushless, the batteries much larger, they are likely to have GPS units and much better quality FPV video cameras, and accessories such as a camera on a gimbal can be slung underneath. The sky is the limit when it comes to high-end multirotor hardware.

This article however is about building a multirotor, and in it we shall look at all aspects of a simple build using off-the-shelf parts. We’ll produce a machine that is a serious aircraft, that’s fun to fly and expandable in different ways as you increase your multirotor flying experience.

We will look at two styles here: a 450 mm frame which will form the basis of the machine we’ll be building, and a smaller frame designed for racing. If you need an analogy to help understand their different characteristics, in this context the 450 mm frame is like a large estate car, while the racing frame is like a racing motorbike. The former is a capable all-rounder that can carry anything a family can throw at it, while the latter is a fast and nimble machine designed for fun and thrills, but lacking significant carrying capacity. Multirotor styles seem to follow fashion for instance, a few years ago the larger frame was king, while it’s fair to say that the racing frame is a far more popular choice today. Yet we’re building a 450 mm craft today, so why is this? The answer comes on several levels. The larger machine is a much easier one to fly than its smaller sibling, and its enhanced carrying capacity means that it is a far more versatile platform for future expansions and upgrades.

When choosing a frame, you will find a bewildering array of models to choose from in supplier catalogues and websites. Many of them are very similar, and among them will be many good choices but, as with so many things, there will be pitfalls to avoid. Fortunately the online multirotor community has produced a huge array of information and component reviews, and you should always check the experiences of other builds with a component before committing your money to it.

The frame we are using for our build is a generic 450 mm frame, with glass reinforced plastic (GRP) arms, and a central platform made using GRP-printed circuit board material, that doubles as a power distribution system. Almost identical frames can be found from multiple suppliers. As is often the case with multirotor frames, there is a means of denoting which is the front of the craft two of the arms are red in colour and we have assembled them in the forward position.

Once you have chosen your frame, the choice of all flight components propellers, motors, motor controllers, and battery stem from the frame’s characteristics. The size of the frame dictates the size of the propeller you will use, which in turn dictates the size and characteristics of the motors that will drive them, and then the appropriate motor controller to drive that, and ultimately the size of the battery required to provide enough power to keep the craft in the air. The first of those choices is relatively simple. There is only a certain amount of space for a propeller on a given multirotor frame without adjacent propellers getting too close to each other, so a certain size range will be a natural progression. For example, our 450 mm frame has a recommended propeller size of 8–10 inches, so we have gone for 8-inch propellers.

There are two figures to look at when choosing a propeller. One is the size, which we have already discussed, while the other is its pitch, or the angle of its blades. This is quoted as the number of inches that represents a theoretical distance it will travel for a single rotation. Going into the full detail of the mechanics of propeller design is beyond the scope of this article, however we are fortunate in that there is usually a recommended pitch range for a given propeller and frame size.

The propeller will sit upon a motor, in almost all cases except small toy machines, a brushless motor. These are motors that accept their electricity as threephase AC over three wires, and require an electronic motor controller for operation. There are three figures that matter with a brushless motor, a figure that represents its dimensions, one that represents its speed, and the voltages and current it is designed for.

The dimensions of the type of motor you will use on a multirotor are expressed as a four-figure number that simply expresses its width and height in mm. So, our motors have a figure of 2212, they are 22 mm wide and 12 mm high. Your frame will have the mounting points ready-drilled for the range of motors you are likely to use with it, and will have an acceptable physical size range as part of its specification.

Motor speed is expressed as a KV value, which denotes the rpm speed increase they deliver per volt. The KV should be matched to the propeller size, for example, our craft with its relatively large 8” propellers has 1000KV motors, while a racing frame with much smaller propellers might have a KV value of well over 2000.

The motor controller will be a small PCB with three sets of connections. There will be the three motor terminals, either large solder pads or wires, two battery input wires, and a control cable terminated in a plug designed for the PWM output of a flight controller, or radio control receiver. It contains a small microcontroller and the power transistors to control the motor. There are motor controllers that will run a motor in both directions, but those you are likely to encounter will be unidirectional. Since half your motors must rotate in the opposite direction to the others, you will need to wire them for reverse operation by reversing two of the three motor wires. The firmware used on the vast majority of motor controllers you will encounter is called BLHeli, and you will find controllers with either 8-bit or 32-bit processors. The important figures on a motor controller are the battery voltage, again expressed in terms of the number of cells, and the peak current it can handle. Both these figures should match their equivalents on your choice of motor.

All of your motors should be the same model, and all should be driven by the same model of controller. For this reason, both motors and controllers are often sold in packs of four. You will also see 4-in-1 controller boards that incorporate all four controllers, these are designed for builds in which space and weight are at a premium, but have the disadvantage that, should you damage one of the controllers, you will have destroyed all four in a stroke. We bought a pack of four BLHeli 32-bit controllers, each with a rating of 2S-4S, and a peak current of 30A.

Probably the most confusing part of specifying components for a multirotor comes in choosing a battery. On the face of it, this should be a straightforward component, but unlike, for example, an alkaline cell for a toy, there are a vast range of different packs available.

All the batteries you should encounter for multirotors share the same chemistry: they are formed from lithium polymer cells, with a nominal voltage of 3.6 V per cell. They are specified with figures as ‘S’ or ‘P’ by their configuration of cells in series or parallel, but in the context of multirotors we are only likely to encounter series packs. Thus, a 1S pack is a single cell, a 2S has two cells, a 3S three, and so on. 1S and 2S packs are in the realm of toys and small craft, so for our purposes we are most likely to find 3S and 4S packs. The higher the voltage, the less current required for a given power, so in our build we opted for a 4S pack.

The other figures on the battery are perhaps the most confusing. There is a capacity rating in mAH, and a mysterious ‘C’ rating. The former is simple enough, a theoretical measure of the quantity of energy it can deliver in terms of what current and for how long, while the latter gives a guide to the peak current it can deliver. Why they don’t simply quote the peak current directly is something of a mystery, but the formula peak current = C rating × capacity delivers the answer.

The peak current must be able to cover the load from the whole machine, with all the motors consuming their full capacity. So with our quadrotor having four motors of maximum 30A, our peak current needs to be at least 120A. Our build has a 4S pack with a capacity of 1800 mAH, or for a more useful version of the same figure, 1.8AH. Its C rating is 75, so the peak current is 75 × 1.8, which is 135A. It certainly can’t supply this figure for any length of time, but it provides a comfortable overhead beyond the capacity of our motors.

Having picked a battery pack, there is one other matter to attend to with respect to the power system on your machine. The battery connector will almost certainly be the popular ‘XT60’ design, and you’ll have an XT60 plug and short lead to fit it. Something is required to safely pass the high current from it to the motor controllers, and that takes the form of a power distribution board. This is a printed circuit board with a master connection for the battery pack and a set of solder pads for each of the motor controllers. Sometimes a four-way motor controller doubles up as a power distribution board, and in our build it is incorporated in the frame, but if you don’t have one, you will need to put one on your list of parts.

The state-of-the-art in-flight controller development is a moving target, and with several years of development now behind us in terms of affordable models, there is a huge choice to be found. At the lower end there are models based upon the technology of a few years ago that will provide a basic flying experience, but if you are building one in 2018 it makes sense to use a controller appropriate to the present.

Of the many choices, we are going to direct you to one of the recent models featuring the STM32 microcontrollers. You will see various different specifications, usually something like ‘F3’, ‘F4’, or ‘F7’ these refer to the different revisions of the STM32 line. The higher the number, the more capable a component, so we would suggest getting an F4 or an F7. The other features you will be looking for are a so-called BEC or battery eliminator circuit to provide low voltage for the electronics, an input voltage range to match your battery choice, and a barometer chip that will allow the controller to maintain an altitude.

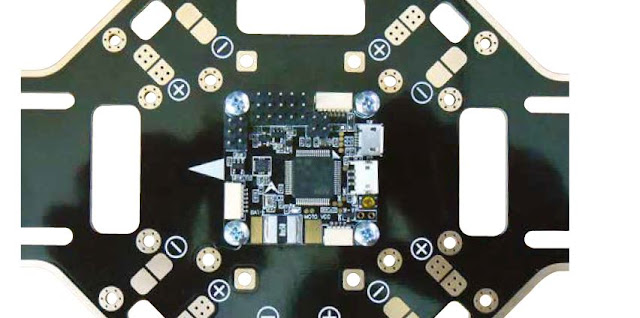

Our choice of an Omnibus F4 controller also gave us the option to monitor the battery current, and an on-screen display system, should we upgrade with a first-person video camera.

The controller itself is only half the story though, because it is simply a piece of hardware. Its real capabilities come through its software, and here at the time this is being written, the choice we would recommend is the popular Betaflight firmware. This should be pre-loaded, but you will often want to upgrade your controller over USB with the latest version.

The trouble with a flight controller though is that it is not a computer like the one on your desk, with a nice user interface, a screen, and keyboard. It has a lot of configurable options, but needs some means to access them. This is something the developers have addressed through a configuration tool, the Betaflight Configurator.

The tool itself takes the form of a Google Chrome extension, that can be found in the Chrome store. It should therefore work on any platform supported by Chrome. Once you have installed it, you may be prompted to download a more recent version. Assuming that your flight controller is plugged into your computer’s USB port, you should be able to click on the ‘connect’ icon in the Betaflight Configurator home screen, and be rewarded by a status screen showing some of the current settings of the board, as well as its altitude. Try lifting the craft, and watch the diagram of it on the screen move accordingly.

On the left-hand side is a menu containing a host of pages with all the detailed Betaflight options. The full functionality of Betaflight is beyond this piece, and while we would like to encourage you to read the full documentation and learn its capabilities, it is strongly recommended that you leave the default settings in place until you are confident with your machine, unless you have real reason to change them. That said, you will probably have need to go into the configuration screen if you have any radio issues, and the receiver screen on which you can check the received values for your different channels. You can also update Betaflight on your controller to its latest version, but this is also an advanced function, and best left alone unless you are confident you know what you are doing.

All the transmitters and receivers you are likely to encounter will use the same frequency band, 2.4GHz. There are no channels as there were in the old days; they share the same frequency and operate by pairing the code on the receiver with that on the transmitter, by pressing a button on the receiver at power-on and starting the transmitter in a special pairing mode.

All transmitters are no longer compatible with each other, there are a variety of competing protocols on the market, and it is easy to make the mistake of buying the wrong ones and ending up with a mismatch. We STRONGLY suggest buying your transmitter and receiver together as a package, to make sure that you know they will work with each other, or at least buying them from the same manufacturer and ensuring that they both speak the same protocol. We bought a relatively inexpensive transmitter, a FlySky, for our build because this article is intended to be as accessible as possible, but you will find transmitters and receivers with prices rising up into the stratosphere.

The receiver will be a small board or module that will connect to the flight controller with a single serial cable. There are several protocols for this communication, for example SBUS, IBUS, or PCM. SBUS seems to be the favoured one, but in our case we must admit that we had significant problems getting our receiver and controller to speak to each other using it, and had to fall back to the somewhat inferior PCM.

The receiver should be able to draw its power from the BEC circuit on the flight controller, but the transmitter will require its own batteries. Frequently these are just domestic AA cells, or sometimes an internal Li-poly pack.

M3 screws, washers, and stand-offs, for example, and cable ties, foam tape, and heat-shrink sleeving. If your flight controller doesn’t have them fitted, then you may also need to find some 0.1” pitch PCB pins. In our case, we had neglected to buy the stand-offs, so we had to make a quick trip to Thingiverse for a model of one to 3D-print.

You will also need to source battery connectors, and we suggest the ubiquitous XT60 variety, and suitable silicone-insulated wire to carry your battery current. Some Velcro battery straps to hold the battery to the frame will also be useful, though at a pinch you could use cable ties for the same task.

Assembly of a commercial multirotor frame should be a straightforward case of screwing it together, but you may wish to mount the motors on the end of the arms and attach the speed controllers to them, such that you attach the arm to the frame as a complete pre-assembled unit. Remember that alternate rotors will need to rotate in opposite directions, so take care to wire your motor controllers appropriately, with two of the wires reversed on two of the arms. In most cases, the controller will have large solder pads for the motor wires; you will need to solder these connections, as well as solder their power wires to the power distribution board. When you are done, place a piece of foam tape onto the underside of the speed controller, and attach the whole to the arm with a cable tie. The foam tape will provide the required cushioning during the vibration of flight.

A pitfall lies in the positioning of the flight controller relative to the frame, it contains the machine’s direction sensor, so in a sense its front and back define the front and back of the finished craft. On the controller PCB will be an arrow, which must be aligned with the front of the frame. We first assembled our build with the controller at 90 degrees to the frame, and spent a while confused because the machine tried to fly sideways.

The flight controller will have ports for the four motor controllers, and you will need to refer to the helpful diagram, provided by the Betaflight control software, to identify which motor should be connected to which one. The SBUS/IBUS/PCM port will also need connecting to the receiver, which you will need to cable-tie securely to the frame with its antenna out of reach of the rotors.

At this point, it’s worth talking about another pitfall. When we first flew our machine, we had a small crash and broke a propeller. Not unexpected, and fortunately we’d bought spare propellers, as you should too. So, why did we crash? Straight out of the box, our machine had extremely sensitive controls, to the extent that though it appeared to work during our tests, in flight it was very difficult to manoeuvre. The solutions were straightforward enough in its default settings, our flight controller was set to fly in acro mode. This is a mode used by racers and other advanced fliers, in which a lot of the stability features in the flight controller software are turned off, and instead of automatically trying to maintain level flight, our machine was all over the place. We had to enable self-levelling mode (called ‘angle’ in Betaflight Configurator, on the modes screen), and bind it to our arm switch for everything to return to normal.

We also decreased the sensitivity of our controls. There are two places this can be done, either by adjusting the rate and exponential settings on our transmitter, or the way we did it in Betaflight Configurator, by reducing the RC rate settings on the PID tuning screen. We strongly suggest that you don’t touch any other PID settings, unless you really know what you are doing.

The propeller fits over a collar that locates on a conical piece of metal, with a screw-on cap holding it all down. Ensure that the caps are screwed down as tightly as possible, or you risk it coming off in flight.

Now, tie the machine down securely to something heavy enough to stop it taking off. Now, reconnect the battery, turn on the transmitter, arm it and, very gently, advance the throttle. It should be obvious if there are any problems, because the machine will vibrate or try to turn. In our case, it tried to turn itself before one of the propellers came off, indicating that we hadn’t tightened its retaining cap sufficiently. Reattaching it and tightening it properly resulted in a stable machine. If you are at that point, then very gently work the controls to see whether the craft tries to turn or move. Do not push the throttle up too far, instead move it up only far enough to prove that it moves.

Disarm the transmitter, and disconnect the battery. Now tie down the four corners of the craft to a secure anchorage with a couple of feet of

lightweight rope. You should then be able to fly it to the limit of the rope, and further test the controls and the stability of the craft.

If your multirotor behaves as expected, you should now be able to fly it for the first time. Find a clear, open space in which you have permission to fly, and in which you can keep the craft over 50 metres away from the general public. Even if you can already fly a multirotor, you should exercise extreme care with the throttle, only advancing it just enough to get the craft into the air and test its manoeuvrability, being ready to safely bring it down and disarm it, should anything be amiss.

Once you are happy with its construction and performance, congratulations! You have made yourself a multirotor! Fly it responsibly, and enjoy it.

Image source: Pixabay

We have been fortunate then, over the last couple of decades, to witness a technological revolution in manufacturing that has brought flight to within the reach of almost anyone. Powerful yet lightweight electric motors, coupled with batteries that have undreamed-of capacities, on machines made from advanced materials by precision mass production techniques, have given us aircraft for pocket money prices. Not only has this been a revolution in terms of cost, it has also given us entirely new craft that would have been impossible to fly before the advent of the computing power required to keep them in the air. A multirotor, commonly referred to as a drone, would have been impossible to fly by any other means than with the help of a computer to keep it in trim, yet now, due to their very low moving parts count, they are the cheapest and most commonly seen form of remote controlled flight. Multirotors have become a part of hackspace culture in a way that other craft have not, so let’s take an in-depth look at them and understand how they are built.

Building blocks on on how to built your own drones

A multirotor has a central fuselage, around which are positioned a set of motors with fixed propellers, or rotors, whose thrust points downwards. A computerised controller monitors a gyroscope and accelerometer, and constantly adjusts the thrust from each motor to maintain the craft in level flight. The vast majority of multirotors have an even number of rotors, so you will commonly see quadcopters with four rotors, hexacopters with six, and octocopters with eight.There are many different types of multirotor, each of which has its own characteristics and applications. A racing quadcopter with extreme

maneuverability, for example, will be completely different to an octocopter used by a broadcaster to carry a TV camera that requires stability and long flight time. It’s time to look at just a few of the types you will commonly find.

SMALL BEGINNINGS

If there is a bottom of the heap in terms of multirotors, it’s probably to be found in your local toy store. Toy micro-quadcopters have been on every child’s Christmas list for a few years now and, while they may be cheap, they are no less fun to fly than their larger counterparts. About ten pounds will snag you the most basic, a tiny quadcopter that will sit in the palm of your hand and has about five minutes’ flight time from a small lithium polymer battery.These machines invariably have little brushed DC motors and very limited outdoor capability, but their flight characteristics are such that, if you can master one, you should find flying a more capable machine to be no problem.

As the budget increases in the field of ready-to-fly multirotors, so do the capabilities of the models in question. The more expensive toy machines now have on-board first-person-view video transmitters and, as the price increases, there is a transition from the world of toys to that of serious machines.

The motors have become brushless, the batteries much larger, they are likely to have GPS units and much better quality FPV video cameras, and accessories such as a camera on a gimbal can be slung underneath. The sky is the limit when it comes to high-end multirotor hardware.

This article however is about building a multirotor, and in it we shall look at all aspects of a simple build using off-the-shelf parts. We’ll produce a machine that is a serious aircraft, that’s fun to fly and expandable in different ways as you increase your multirotor flying experience.

IT’S ALL IN THE FRAME

Choosing your multirotor style

Once a choice has been made over the number of rotors, there are a number of styles, depending upon the desired characteristics of the final craft. Which style you opt for will have an impact across many of the components that you will need to source for your build, but the most fundamental of those components is the one most closely associated with your style. The frame provides a platform to support the motors, batteries, and electronics, and must be rigid enough to permit the aircraft to fly without vibration or distortion.

We will look at two styles here: a 450 mm frame which will form the basis of the machine we’ll be building, and a smaller frame designed for racing. If you need an analogy to help understand their different characteristics, in this context the 450 mm frame is like a large estate car, while the racing frame is like a racing motorbike. The former is a capable all-rounder that can carry anything a family can throw at it, while the latter is a fast and nimble machine designed for fun and thrills, but lacking significant carrying capacity. Multirotor styles seem to follow fashion for instance, a few years ago the larger frame was king, while it’s fair to say that the racing frame is a far more popular choice today. Yet we’re building a 450 mm craft today, so why is this? The answer comes on several levels. The larger machine is a much easier one to fly than its smaller sibling, and its enhanced carrying capacity means that it is a far more versatile platform for future expansions and upgrades.

START IN THE MIDDLE

At the centre of a multirotor frame is always a platform for the electronics and battery, from which radiate the arms that carry the motors. We’re looking at a quadcopter here, so in our case there are four arms. The electronics platform is frequently made into an enclosure in the space between two plates, this provides extra rigidity, as well as protection for the fragile components. A very popular choice for racing frames, due to its high strength and low weight, is a carbon fibre frame.When choosing a frame, you will find a bewildering array of models to choose from in supplier catalogues and websites. Many of them are very similar, and among them will be many good choices but, as with so many things, there will be pitfalls to avoid. Fortunately the online multirotor community has produced a huge array of information and component reviews, and you should always check the experiences of other builds with a component before committing your money to it.

The frame we are using for our build is a generic 450 mm frame, with glass reinforced plastic (GRP) arms, and a central platform made using GRP-printed circuit board material, that doubles as a power distribution system. Almost identical frames can be found from multiple suppliers. As is often the case with multirotor frames, there is a means of denoting which is the front of the craft two of the arms are red in colour and we have assembled them in the forward position.

KEEPING IT IN THE AIR

Flight component choice

There are two figures to look at when choosing a propeller. One is the size, which we have already discussed, while the other is its pitch, or the angle of its blades. This is quoted as the number of inches that represents a theoretical distance it will travel for a single rotation. Going into the full detail of the mechanics of propeller design is beyond the scope of this article, however we are fortunate in that there is usually a recommended pitch range for a given propeller and frame size.

SPIN ME RIGHT ROUND

Propellers are normally sold in packs of two, containing both a clockwise and anti-clockwise component, and are quoted as a four-figure number, denoting their size and pitch. Our 8-inch propellers have a pitch of 4.5, and thus are 8045 propellers. If you are not a propeller guru, and we certainly aren’t, look online at similar builds to the one you are embarking upon, and base your choices upon theirs.The propeller will sit upon a motor, in almost all cases except small toy machines, a brushless motor. These are motors that accept their electricity as threephase AC over three wires, and require an electronic motor controller for operation. There are three figures that matter with a brushless motor, a figure that represents its dimensions, one that represents its speed, and the voltages and current it is designed for.

The dimensions of the type of motor you will use on a multirotor are expressed as a four-figure number that simply expresses its width and height in mm. So, our motors have a figure of 2212, they are 22 mm wide and 12 mm high. Your frame will have the mounting points ready-drilled for the range of motors you are likely to use with it, and will have an acceptable physical size range as part of its specification.

Motor speed is expressed as a KV value, which denotes the rpm speed increase they deliver per volt. The KV should be matched to the propeller size, for example, our craft with its relatively large 8” propellers has 1000KV motors, while a racing frame with much smaller propellers might have a KV value of well over 2000.

WITH GREAT POWER COMES MOTION

Finally, the voltage and current figures of the motor define what motor controller and battery choices you should make. The voltage is often expressed in terms of battery pack size, as well as voltage, for example our motors are expressed as 2S-4S, meaning a lithium polymer battery with between 2 and 4 cells in series. There should also be a peak current figure that will be necessary when picking a speed controller.The motor controller will be a small PCB with three sets of connections. There will be the three motor terminals, either large solder pads or wires, two battery input wires, and a control cable terminated in a plug designed for the PWM output of a flight controller, or radio control receiver. It contains a small microcontroller and the power transistors to control the motor. There are motor controllers that will run a motor in both directions, but those you are likely to encounter will be unidirectional. Since half your motors must rotate in the opposite direction to the others, you will need to wire them for reverse operation by reversing two of the three motor wires. The firmware used on the vast majority of motor controllers you will encounter is called BLHeli, and you will find controllers with either 8-bit or 32-bit processors. The important figures on a motor controller are the battery voltage, again expressed in terms of the number of cells, and the peak current it can handle. Both these figures should match their equivalents on your choice of motor.

All of your motors should be the same model, and all should be driven by the same model of controller. For this reason, both motors and controllers are often sold in packs of four. You will also see 4-in-1 controller boards that incorporate all four controllers, these are designed for builds in which space and weight are at a premium, but have the disadvantage that, should you damage one of the controllers, you will have destroyed all four in a stroke. We bought a pack of four BLHeli 32-bit controllers, each with a rating of 2S-4S, and a peak current of 30A.

POWERING IT ALL

Choosing a battery

Probably the most confusing part of specifying components for a multirotor comes in choosing a battery. On the face of it, this should be a straightforward component, but unlike, for example, an alkaline cell for a toy, there are a vast range of different packs available.

All the batteries you should encounter for multirotors share the same chemistry: they are formed from lithium polymer cells, with a nominal voltage of 3.6 V per cell. They are specified with figures as ‘S’ or ‘P’ by their configuration of cells in series or parallel, but in the context of multirotors we are only likely to encounter series packs. Thus, a 1S pack is a single cell, a 2S has two cells, a 3S three, and so on. 1S and 2S packs are in the realm of toys and small craft, so for our purposes we are most likely to find 3S and 4S packs. The higher the voltage, the less current required for a given power, so in our build we opted for a 4S pack.

The other figures on the battery are perhaps the most confusing. There is a capacity rating in mAH, and a mysterious ‘C’ rating. The former is simple enough, a theoretical measure of the quantity of energy it can deliver in terms of what current and for how long, while the latter gives a guide to the peak current it can deliver. Why they don’t simply quote the peak current directly is something of a mystery, but the formula peak current = C rating × capacity delivers the answer.

The peak current must be able to cover the load from the whole machine, with all the motors consuming their full capacity. So with our quadrotor having four motors of maximum 30A, our peak current needs to be at least 120A. Our build has a 4S pack with a capacity of 1800 mAH, or for a more useful version of the same figure, 1.8AH. Its C rating is 75, so the peak current is 75 × 1.8, which is 135A. It certainly can’t supply this figure for any length of time, but it provides a comfortable overhead beyond the capacity of our motors.

POWER UP

Lithium polymer cells are both powerful and compact, but that power comes at a price. They can be hazardous if not treated with care, as when they degrade they can build up hydrogen gas within them, and if punctured they can catch fire. They must always be stored somewhere fireproof and in a charged state, and never overcharged or aggressively discharged. You will find two connectors on a multi-cell lithium polymer pack: the main power connector, and a multi-way charge balancing connector, allowing the charger to monitor the voltage in each individual cell. Always use a proper lithium polymer charger with a receptacle for this balance connector, and it is imperative that you read the instructions and safety notes that come with your cells.Having picked a battery pack, there is one other matter to attend to with respect to the power system on your machine. The battery connector will almost certainly be the popular ‘XT60’ design, and you’ll have an XT60 plug and short lead to fit it. Something is required to safely pass the high current from it to the motor controllers, and that takes the form of a power distribution board. This is a printed circuit board with a master connection for the battery pack and a set of solder pads for each of the motor controllers. Sometimes a four-way motor controller doubles up as a power distribution board, and in our build it is incorporated in the frame, but if you don’t have one, you will need to put one on your list of parts.

CONTROLLING IT ALL

The final large on-board component that we haven’t covered is the flight controller. This is a small computer that monitors an accelerometer and gyroscope on a chip, and continually adjusts the power to the rotors to keep the craft stable, in the desired heading and altitude. Above all other components, this is the one that has made multirotor flight possible maintaining stable multirotor flight unaided would have been beyond the abilities of human pilots.The state-of-the-art in-flight controller development is a moving target, and with several years of development now behind us in terms of affordable models, there is a huge choice to be found. At the lower end there are models based upon the technology of a few years ago that will provide a basic flying experience, but if you are building one in 2018 it makes sense to use a controller appropriate to the present.

Of the many choices, we are going to direct you to one of the recent models featuring the STM32 microcontrollers. You will see various different specifications, usually something like ‘F3’, ‘F4’, or ‘F7’ these refer to the different revisions of the STM32 line. The higher the number, the more capable a component, so we would suggest getting an F4 or an F7. The other features you will be looking for are a so-called BEC or battery eliminator circuit to provide low voltage for the electronics, an input voltage range to match your battery choice, and a barometer chip that will allow the controller to maintain an altitude.

Our choice of an Omnibus F4 controller also gave us the option to monitor the battery current, and an on-screen display system, should we upgrade with a first-person video camera.

The controller itself is only half the story though, because it is simply a piece of hardware. Its real capabilities come through its software, and here at the time this is being written, the choice we would recommend is the popular Betaflight firmware. This should be pre-loaded, but you will often want to upgrade your controller over USB with the latest version.

THE BETAFLIGHT CONFIGURATOR SOFTWARE

Betaflight is a firmware package for multirotor flight controllers, that sits on the STM32 inside your controller, and does its job of keeping your craft in the air.The trouble with a flight controller though is that it is not a computer like the one on your desk, with a nice user interface, a screen, and keyboard. It has a lot of configurable options, but needs some means to access them. This is something the developers have addressed through a configuration tool, the Betaflight Configurator.

The tool itself takes the form of a Google Chrome extension, that can be found in the Chrome store. It should therefore work on any platform supported by Chrome. Once you have installed it, you may be prompted to download a more recent version. Assuming that your flight controller is plugged into your computer’s USB port, you should be able to click on the ‘connect’ icon in the Betaflight Configurator home screen, and be rewarded by a status screen showing some of the current settings of the board, as well as its altitude. Try lifting the craft, and watch the diagram of it on the screen move accordingly.

On the left-hand side is a menu containing a host of pages with all the detailed Betaflight options. The full functionality of Betaflight is beyond this piece, and while we would like to encourage you to read the full documentation and learn its capabilities, it is strongly recommended that you leave the default settings in place until you are confident with your machine, unless you have real reason to change them. That said, you will probably have need to go into the configuration screen if you have any radio issues, and the receiver screen on which you can check the received values for your different channels. You can also update Betaflight on your controller to its latest version, but this is also an advanced function, and best left alone unless you are confident you know what you are doing.

COMMANDING YOUR CRAFT

Choosing a radio

In earlier decades, remote-control systems for model cars and aircraft were simple affairs. All transmitters and receivers were compatible with each other, so long as they shared the same frequency, and they would have been paired with each other by having matching plug-in quartz crystals. Their modern descendants have a hugely expanded feature set, but at the cost of greater complexity and a few pitfalls for the unwary buyer.All the transmitters and receivers you are likely to encounter will use the same frequency band, 2.4GHz. There are no channels as there were in the old days; they share the same frequency and operate by pairing the code on the receiver with that on the transmitter, by pressing a button on the receiver at power-on and starting the transmitter in a special pairing mode.

All transmitters are no longer compatible with each other, there are a variety of competing protocols on the market, and it is easy to make the mistake of buying the wrong ones and ending up with a mismatch. We STRONGLY suggest buying your transmitter and receiver together as a package, to make sure that you know they will work with each other, or at least buying them from the same manufacturer and ensuring that they both speak the same protocol. We bought a relatively inexpensive transmitter, a FlySky, for our build because this article is intended to be as accessible as possible, but you will find transmitters and receivers with prices rising up into the stratosphere.

The receiver will be a small board or module that will connect to the flight controller with a single serial cable. There are several protocols for this communication, for example SBUS, IBUS, or PCM. SBUS seems to be the favoured one, but in our case we must admit that we had significant problems getting our receiver and controller to speak to each other using it, and had to fall back to the somewhat inferior PCM.

The receiver should be able to draw its power from the BEC circuit on the flight controller, but the transmitter will require its own batteries. Frequently these are just domestic AA cells, or sometimes an internal Li-poly pack.

BUILDING THE MULTIROTOR

So, given the previous sections, you should now be sitting at your bench with all the parts of a multirotor set out in front of you. One might think then that now would follow a step-by-step assembly guide. But perhaps surprisingly that’s not exactly the direction we’ll take. You’re HackSpace magazine readers, you will know one end of a screwdriver or a soldering iron from the other and that’s, to a large extent, the skill you’ll need to assemble a multirotor. Off-the-shelf components are designed to be assembled in this way, so instead of giving you a screw-by-screw guide, it’s better to pull out a little on the mundane, and zoom in only on the unusual or problematic parts. Before you start though, it’s worth ensuring that you have the sundries you will need.

M3 screws, washers, and stand-offs, for example, and cable ties, foam tape, and heat-shrink sleeving. If your flight controller doesn’t have them fitted, then you may also need to find some 0.1” pitch PCB pins. In our case, we had neglected to buy the stand-offs, so we had to make a quick trip to Thingiverse for a model of one to 3D-print.

You will also need to source battery connectors, and we suggest the ubiquitous XT60 variety, and suitable silicone-insulated wire to carry your battery current. Some Velcro battery straps to hold the battery to the frame will also be useful, though at a pinch you could use cable ties for the same task.

Assembly of a commercial multirotor frame should be a straightforward case of screwing it together, but you may wish to mount the motors on the end of the arms and attach the speed controllers to them, such that you attach the arm to the frame as a complete pre-assembled unit. Remember that alternate rotors will need to rotate in opposite directions, so take care to wire your motor controllers appropriately, with two of the wires reversed on two of the arms. In most cases, the controller will have large solder pads for the motor wires; you will need to solder these connections, as well as solder their power wires to the power distribution board. When you are done, place a piece of foam tape onto the underside of the speed controller, and attach the whole to the arm with a cable tie. The foam tape will provide the required cushioning during the vibration of flight.

A pitfall lies in the positioning of the flight controller relative to the frame, it contains the machine’s direction sensor, so in a sense its front and back define the front and back of the finished craft. On the controller PCB will be an arrow, which must be aligned with the front of the frame. We first assembled our build with the controller at 90 degrees to the frame, and spent a while confused because the machine tried to fly sideways.

The flight controller will have ports for the four motor controllers, and you will need to refer to the helpful diagram, provided by the Betaflight control software, to identify which motor should be connected to which one. The SBUS/IBUS/PCM port will also need connecting to the receiver, which you will need to cable-tie securely to the frame with its antenna out of reach of the rotors.

COMMISSIONING YOUR MACHINE

When you have assembled the machine, before you fit the propellers, you should first give it a full visual check, to ensure that you catch obvious problems. Then, connect a USB cable to the flight controller, plug it into your PC, and run the Betaflight Configurator software. This should power up only the controller and receiver, and allow you to verify that the controller and radio are working, and configure any settings you may need. Only when you are satisfied that all is in order should you connect the battery, and spin up the motors by operating the throttle. With no propellers fitted, there will be vibration when the motors spin up, but the scope for damage will be limited. You should be able to tilt the machine and see the different motors spin up as it attempts to right itself.At this point, it’s worth talking about another pitfall. When we first flew our machine, we had a small crash and broke a propeller. Not unexpected, and fortunately we’d bought spare propellers, as you should too. So, why did we crash? Straight out of the box, our machine had extremely sensitive controls, to the extent that though it appeared to work during our tests, in flight it was very difficult to manoeuvre. The solutions were straightforward enough in its default settings, our flight controller was set to fly in acro mode. This is a mode used by racers and other advanced fliers, in which a lot of the stability features in the flight controller software are turned off, and instead of automatically trying to maintain level flight, our machine was all over the place. We had to enable self-levelling mode (called ‘angle’ in Betaflight Configurator, on the modes screen), and bind it to our arm switch for everything to return to normal.

We also decreased the sensitivity of our controls. There are two places this can be done, either by adjusting the rate and exponential settings on our transmitter, or the way we did it in Betaflight Configurator, by reducing the RC rate settings on the PID tuning screen. We strongly suggest that you don’t touch any other PID settings, unless you really know what you are doing.

READY FOR FLIGHT

A multirotor might seem fairly harmless, but it can be a dangerous machine. There is significant energy in those propellers, and catching a finger or hand in one at full speed can cause injury and pain. Once we attach the propellers, it is important to treat the machine as potentially dangerous. Be careful not to come into contact with spinning propellers, and only arm and operate it when you are sure it’s in a safe environment.The propeller fits over a collar that locates on a conical piece of metal, with a screw-on cap holding it all down. Ensure that the caps are screwed down as tightly as possible, or you risk it coming off in flight.

Now, tie the machine down securely to something heavy enough to stop it taking off. Now, reconnect the battery, turn on the transmitter, arm it and, very gently, advance the throttle. It should be obvious if there are any problems, because the machine will vibrate or try to turn. In our case, it tried to turn itself before one of the propellers came off, indicating that we hadn’t tightened its retaining cap sufficiently. Reattaching it and tightening it properly resulted in a stable machine. If you are at that point, then very gently work the controls to see whether the craft tries to turn or move. Do not push the throttle up too far, instead move it up only far enough to prove that it moves.

Disarm the transmitter, and disconnect the battery. Now tie down the four corners of the craft to a secure anchorage with a couple of feet of

lightweight rope. You should then be able to fly it to the limit of the rope, and further test the controls and the stability of the craft.

If your multirotor behaves as expected, you should now be able to fly it for the first time. Find a clear, open space in which you have permission to fly, and in which you can keep the craft over 50 metres away from the general public. Even if you can already fly a multirotor, you should exercise extreme care with the throttle, only advancing it just enough to get the craft into the air and test its manoeuvrability, being ready to safely bring it down and disarm it, should anything be amiss.

Once you are happy with its construction and performance, congratulations! You have made yourself a multirotor! Fly it responsibly, and enjoy it.

COMMENTS